Do your jewelry designs include fine feature detail? Do you need the very best lost wax casting? There are many considerations to keep in mind in order to maintain perspective while reviewing the various 3D printer technologies available to jewelers.

Make your decision with confidence

By staying focused you can avoid being distracted by features and benefits that might sound impressive but are not the right solution for your business. Keep in mind, technology is simply a tool for achieving your goals.

Carefully weigh your options. Low-cost 3D printers can be alluring but will disappoint if you are particular about the accuracy of your design. There is no single answer for everyone which is why you need to remain focused on what you want to achieve. Making printing speed a key deciding factor could cost you in time and labor when the quality of the castings do not meet your expectations.

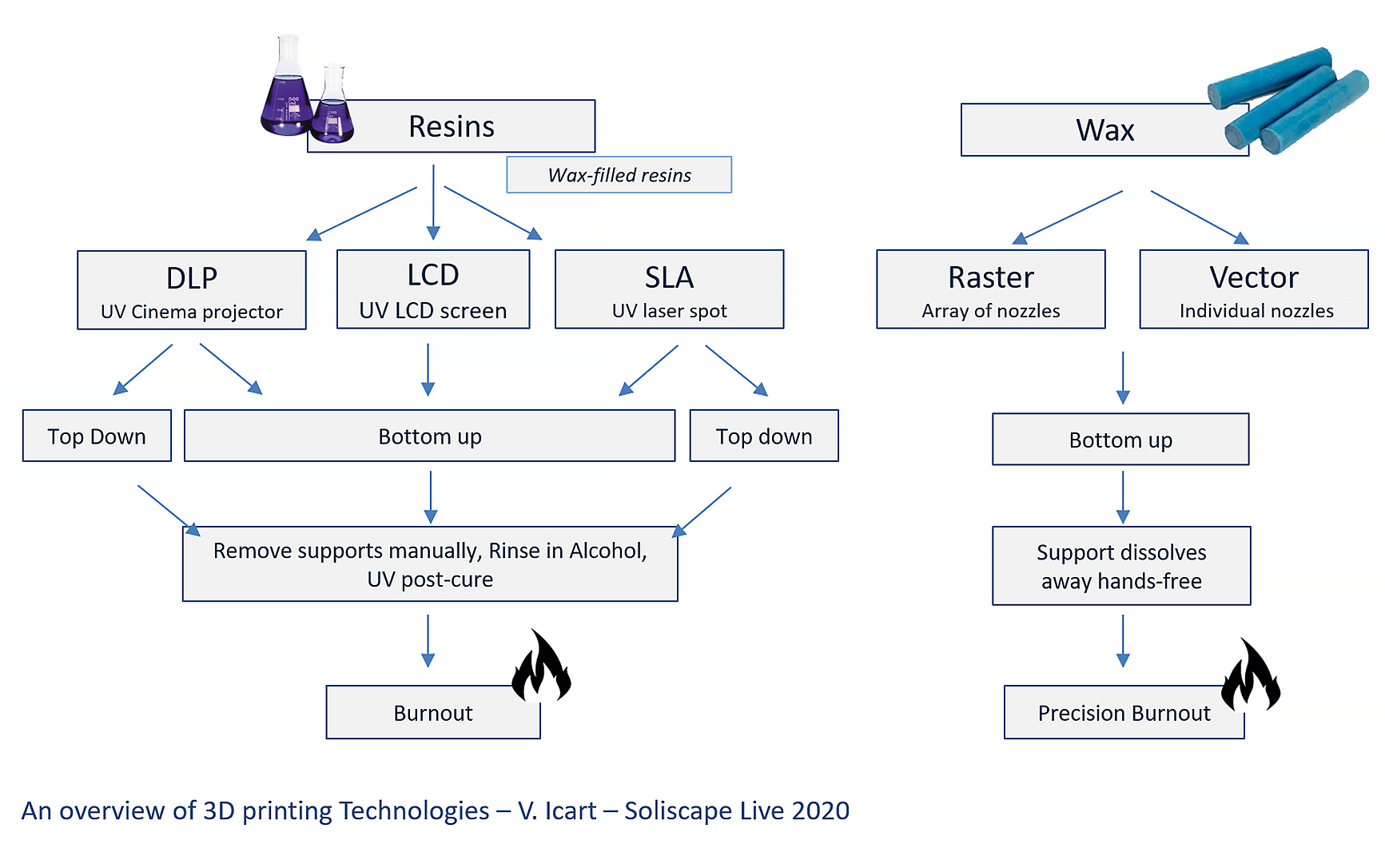

Overview of jewelry 3D printer technologies

3D printers used in jewelry can generally be categorized into 2 basic technologies. One uses a photopolymer material that is solidified by UV light, typically referred to as a resin 3D printer. The other is a 2-material system where waxes are jetted in the form of liquid droplets. In both cases the 3d model is built layer by layer as the build plate is either lowered or raised depending upon the printing technology.

Jewelry focused

Solidscape wax 3D printers are designed for the intricacies of fine jewelry. The system comes with slicing software for jewelry manufacturing. Easy-to-use menus set printing parameters to perfection. The software automates the exact support structure for each geometry, releasing the designer from the time-consuming task of configuring supports.

What is design freedom?

Inspired creations emerge from the freedom to explore form and function. Jewelry is an object of beauty whose design is influenced by how it relates to the body and the experience of wearing it. Interrupting this flow of thought to engineer support stands and their removal is contrary to the creative process.

“It is necessary to keep one’s compass in one’s eyes and not in the hand, for the hands execute, but the eye judges.”

― Michelangelo

Produce exactly what you design

The time it takes a Solidscape to precisely deposit build and support materials and perfect the surface finish between each layer ultimately saves you time and labor in post processing. You get a model of uncompromising design detail that carries through to the final casting. The quality of your work will set you apart from the competition.

- Safe, non-toxic model and support materials

- Support wax dissolves hands-free in a liquid bath.

- Accurate castings; clean burnout, no shrinkage or ashen residue