Reliable, durable, high quality wax 3D printing material for high precision lost wax casting

Produce intricately detailed, dimensionally accurate, directly castable fine wax patterns not possible with any other process, material or 3D printer. Solidscape’s Midas and Melt 3D printer wax and support material delivers hands-off high performance.

Midas: High performance wax for flawless castings

Build durable, superior quality models with Midas wax engineered specifically for high precision investment casting. Use your existing investment casting processes and burnout schedules to achieve higher casting yields and superior, smooth castings. No guessing. No trial and error. Just perfect wax models every time.

Only Solidscape Midas 3D printer wax delivers:

- Durable, true-to-CAD models — no warping, stretching or distortion common with photopolymer resin builds

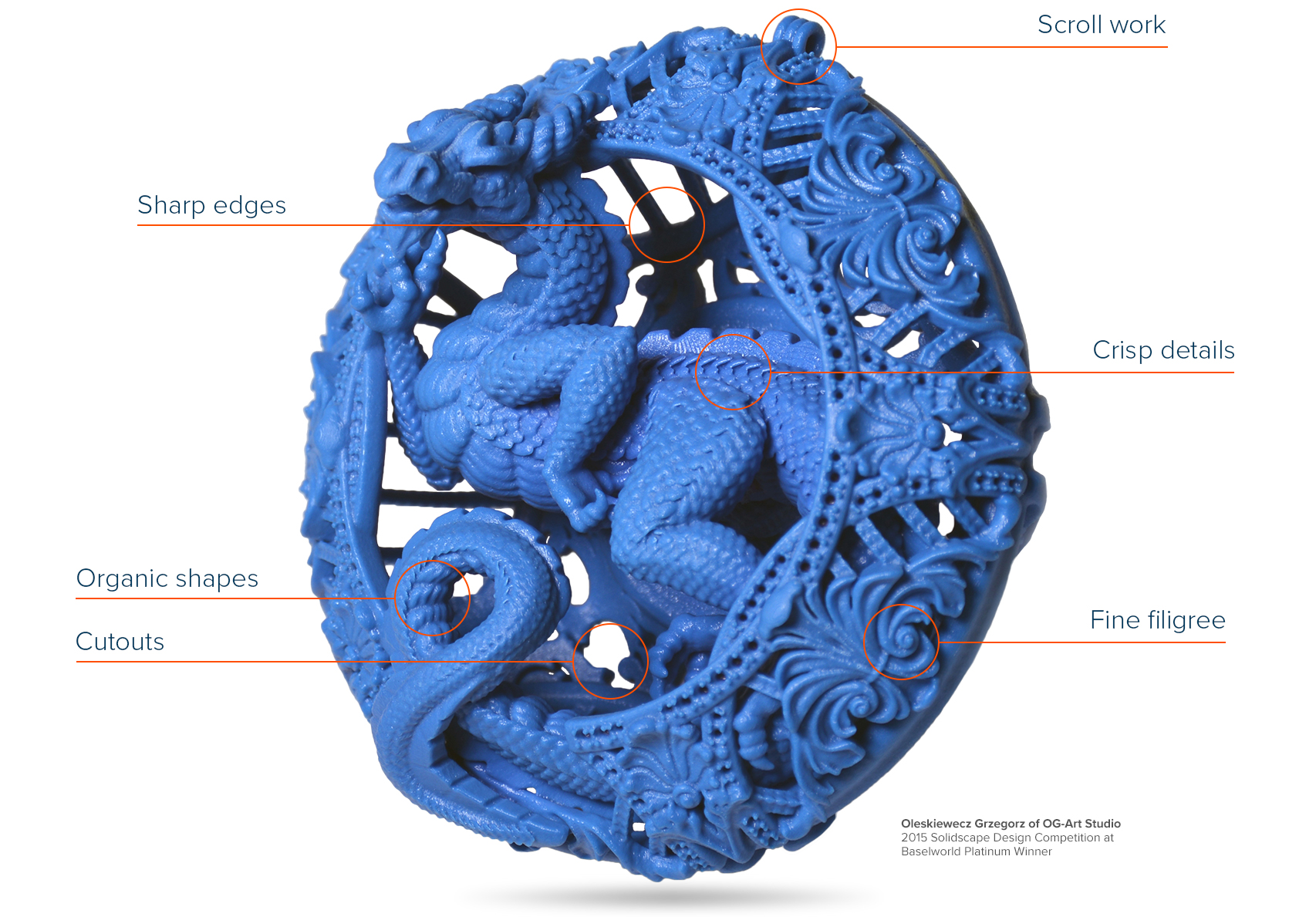

- Complex geometries, overhangs and undercuts, flat planes, consistent wall thickness, sharp edges and fine features

- Direct investment casting in all castable materials, from precious metals to industrial alloys — the only choice for casting in platinum

- Clean, complete burnout — no ash, residue or porosity

- Ultra-accurate, high integrity castings with tight tolerances — no thermal expansion

- The best surface finish in the industry

“Crayon” form offers simplified dust-free loading of pre-measured amounts, eliminating operator error

Only with Solidscape

Rollover for detail

Solidscape 3D printers does the work of supporting the model as it prints by surrounding it with Melt, a dissolvable support material. The automated Melt structure maintains the integrity of the design by uniformly supporting every geometry at every layer throughout the entire printing process. The result is accurate fine feature detail, limitless complexity and a smooth surface finish. No need to create supports in CAD and nothing to remove in post processing. Melt dissolves away in a non-toxic liquid — leaving a pristine wax pattern directly ready for casting.

Only Solidscape Melt 3D printer support material delivers:

- Fine feature designs are fully supported during the build

- Total design freedom — Melt completely dissolves away, hands free

- Complexity — Moving from thick to thin profiles? Interlocking components? Square edges or flat planes? Irregular stone settings? No problem.

- Accuracy beyond any photopolymer 3D printer capabilities