Customized performance

for custom design

When every piece is unique and your goal is to deliver perfection, the S360 with XDP has all the flexibility you need. eXtra Dimensional Printing (XDP) technology bundles the best of the S-Series in a single printer. With the S360 you can optimize every print run for the custom designs of each.

S325 Wax Model 3D Printer for Jewelry

The Solidscape® S325 delivers the extraordinary precision you need at the right price. Jewelers are free to design innovative custom jewelry without limits and manufacture with less work than with other technologies.

S360 Wax Model 3D Printer for Jewelry

The Solidscape® S360 with XDP uniquely gives you the choice between printing in SCP or solidjet mode, giving you the most flexibility available in a single printer in the high precision S-Series of 3D wax printers. For shops doing a variety of jewelry, it hits the X- factor across the board.

The Solidscape® S390 has the fastest print speed and delivers Solidscape’s extraordinary precision and accuracy. The S390 enables jewelry manufacturers who produce an average of 10 – 12 models per day to significantly ramp up output, slash prototyping and production time, and maximize both personnel and printer resources.

Design freedom

Innovate without limits, eclipse the competition.

“

For every profession out there, having the right tools is extremely important. Solidscape machines are worth their weight in gold.

- Hagop Matossian, Bostonian Jewelers and Manufacturers

”

Which S300 Series 3D printer is right for your business?

for jewelry manufacturers and retailers

The Solidscape S325, S360, and S390 are engineered specifically for custom jewelry production

S325 | S360 | ||

|---|---|---|---|

| Business model | Small manufacturer of fine jewelry requiring excellent model quality and 25 micron resolution | Manufacturer of high-end custom jewelry requiring flexibility between print runs | Manufacturer of fine jewelry for whom design freedom and speed are both important |

| Production Volume | Production volume of precise pieces per day | Production volume of precise pieces per day | Highest production volume of precise pieces per day |

The Solidscape S325, S360, and S390 are engineered specifically for custom jewelry production

| Business model | Production Volume | Lifetime Printhead Warranty | |

|---|---|---|---|

| S325 | Small manufacturer of fine jewelry requiring excellent model quality and 25 micron resolution | Production volume of precise pieces per day | N/A |

| S350 | Manufacturer of high-end jewelry requiring the highest resolution | Production volume of precise pieces per day | N/A |

| S370 | Manufacturer of high-end jewelry more throughput | High production volume of precise pieces per day | N/A |

| S390 | Manufacturer of fine jewelry for whom design freedom and speed are both important | Highest production volume of precise pieces per day | Yes |

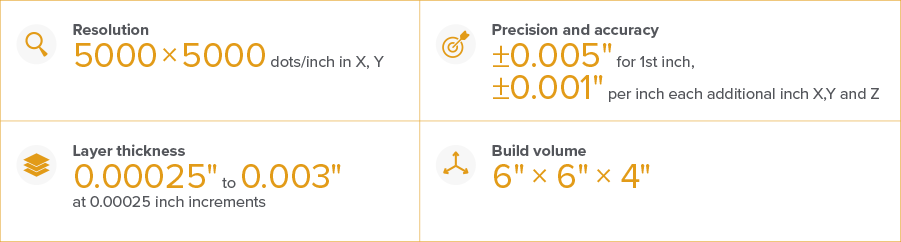

Inches |

|

| Resolution | 5000 × 5000 dots/inch in X, Y |

| Precision and Accuracy | ±0.005" for 1st inch, ±0.001" per inch each additional inch X,Y and Z |

| Layer Thickness | 0.00025" to 0.003" at 0.00025 inch increments |

| Build Volume | 6" × 6" × 4" |

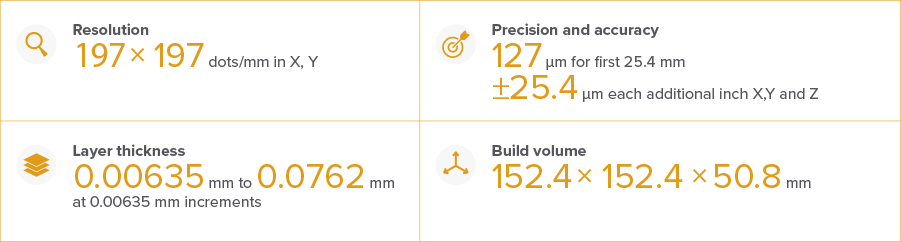

Millimeters |

|

| Resolution | 197x197 dots/mm in X,Y |

| Precision and Accuracy | 127 µm for first 25.4 mm ±25.4 µm each additional inch X,Y and Z |

| Layer Thickness | 0.00635 mm to 0.0762 mm at 0.00635 mm increments |

| Build Volume | 152.4 × 152.4 × 50.8 mm |

| Layer Thickness: | 0.001 inch (0.0254mm) |

| Resolution: | 5000 dots/inch (197 X 197 dots/mm) in X, Y |

| Accuracy: | ±0.005 inch (127 μm) for 1st inch (25.4 mm), ±0.001 inch/inch (25.4 μm) each additional inch X,Y and Z |

| Surface Finish: | Layer thickness-dependent, up to 32 micro-inches (RMS) |

| Start Process: | Fully automated, one-touch operation |

| Status Monitoring: | Fully automated fault detection, restarts build from point of interruption |

| Calibration Capacity: | Quicker calibration and ability to select calibration frequency means less wasted material |

| Dimensions: | 21.4 x 18 x 16 inches (558 x 495 x 419 mm) |

| Build Envelope: | 6 x 6 x 4 inches (152.4 x 152.4 x 101.6 mm) |

| Weight: | 80 lbs (36 kg) |

| Power: | 100 - 240 V Required |

| Operating Temperature: | 60° to 75°F (16° to 24°C) |

| Humidity: | 40-60% |

| Agency Compliance: | CE Certified, FCC Class B approved, TUV certified EN 60950 Compliant |

| Midas Castable Material: | Proprietary model material formulated for clean burnout, producing 100% direct casting results |

| MeltDissolvable Support: | Proprietary support material engineered to dissolve completely, hands-free, resulting in superior surface finish |

| Material Capacity: | Larger tanks require less filling and allow for longer print runs |

| Material Monitoring: | Display indicates build and support material levels accurately in 10% increments |

| One-Click Software: | Automatically formats CAD files for 3D printing |

| CAD File Input: | .stl and .slc files |

| System: | Windows, PC-to-printer connectivity via high-speed USB 2.0 or Ethernet |

| Layer Thickness: | User Selectable – 0.00025 inch (0.00635 mm) to 0.003 inch (0.0762 mm) at 0.00025 (0.00635 mm) increments |

| Resolution: | 5000 dots/inch (197 X 197 dots/mm) in X, Y |

| Accuracy: | ±0.005 inch (127 μm) for 1st inch (25.4 mm), ±0.001 inch/inch (25.4 μm) each additional inch X,Y and Z |

| Surface Finish: | Layer thickness-dependent, up to 32 micro-inches (RMS) |

| Start Process: | Fully automated, one-touch operation |

| Status Monitoring: | Fully automated fault detection, restarts build from point of interruption |

| Calibration Capacity: | Quicker calibration and ability to select calibration frequency means less wasted material |

| Dimensions: | 21.4 x 18 x 16 inches (558 x 495 x 419 mm) |

| Build Envelope: | 6 x 6 x 4 inches (152.4 x 152.4 x 101.6 mm) |

| Weight: | 80 lbs (36 kg) |

| Power: | 100 - 240 V Required |

| Operating Temperature: | 60° to 75°F (16° to 24°C) |

| Humidity: | 40-60% |

| Agency Compliance: | CE Certified, FCC Class B approved, TUV certified EN 60950 Compliant |

| Midas Castable Material: | Proprietary model material formulated for clean burnout, producing 100% direct casting results |

| MeltDissolvable Support: | Proprietary support material engineered to dissolve completely, hands-free, resulting in superior surface finish |

| Material Capacity: | Larger tanks require less filling and allow for longer print runs |

| Material Monitoring: | Display indicates build and support material levels accurately in 10% increments |

| One-Click Software: | Automatically formats CAD files for 3D printing |

| CAD File Input: | .stl and .slc files |

| System: | Windows, PC-to-printer connectivity via high-speed USB 2.0 or Ethernet |

| Layer Thickness: | User Selectable - 0.00025 inch (0.00635 mm) to 0.0015 inch (0.038 mm) at 0.00025 (0.00635 mm) increments |

| Resolution: | 5000 dots/inch (197 X 197 dots/mm) in X, Y |

| Accuracy: | ±0.005 inch (127 μm) for 1st inch (25.4 mm), ±0.001 inch/inch (25.4 μm) each additional inch X,Y and Z |

| Surface Finish: | Layer thickness-dependent, up to 32 micro-inches (RMS) |

| Start Process: | Fully automated, one-touch operation |

| Status Monitoring: | Fully automated fault detection, restarts build from point of interruption |

| Calibration Capacity: | Quicker calibration and ability to select calibration frequency means less wasted material |

| Dimensions: | 21.4 x 18 x 16 inches (558 x 495 x 419 mm) |

| Build Envelope: | 6 x 6 x 4 inches (152.4 x 152.4 x 101.6 mm) |

| Weight: | 80 lbs (36 kg) |

| Power: | 100 - 240 V Required |

| Operating Temperature: | 60° to 75°F (16° to 24°C) |

| Humidity: | 40-60% |

| Agency Compliance: | CE Certified, FCC Class B approved, TUV certified EN 60950 Compliant |

| Midas Castable Material: | Proprietary model material formulated for clean burnout, producing 100% direct casting results |

| MeltDissolvable Support: | Proprietary support material engineered to dissolve completely, hands-free, resulting in superior surface finish |

| Material Capacity: | Larger tanks require less filling and allow for longer print runs |

| Material Monitoring: | Display indicates build and support material levels accurately in 10% increments |

| One-Click Software: | Automatically formats CAD files for 3D printing |

| CAD File Input: | .stl and .slc files |

| System: | Windows, PC-to-printer connectivity via high-speed USB 2.0 or Ethernet |

| Layer Thickness: | User Selectable - 0.00025 inch (0.00635 mm) to 0.0015 inch (0.038 mm) at 0.00025 (0.00635 mm) increments |

| Resolution: | 5000 dots/inch (197 X 197 dots/mm) in X, Y |

| Accuracy: | ±0.005 inch (127 μm) for 1st inch (25.4 mm), ±0.001 inch/inch (25.4 μm) each additional inch X,Y and Z |

| Surface Finish: | Layer thickness-dependent, up to 32 micro-inches (RMS) |

| Start Process: | Fully automated, one-touch operation |

| Status Monitoring: | Fully automated fault detection, restarts build from point of interruption |

| Calibration Capacity: | Quicker calibration and ability to select calibration frequency means less wasted material |

| Dimensions: | 21.4 x 18 x 16 inches (558 x 495 x 419 mm) |

| Build Envelope: | 6 x 6 x 4 inches (152.4 x 152.4 x 101.6 mm) |

| Weight: | 80 lbs (36 kg) |

| Power: | 100 - 240 V Required |

| Operating Temperature: | 60° to 75°F (16° to 24°C) |

| Humidity: | 40-60% |

| Agency Compliance: | CE Certified, FCC Class B approved, TUV certified EN 60950 Compliant |

| Midas Castable Material: | Proprietary model material formulated for clean burnout, producing 100% direct casting results |

| MeltDissolvable Support: | Proprietary support material engineered to dissolve completely, hands-free, resulting in superior surface finish |

| Material Capacity: | Larger tanks require less filling and allow for longer print runs |

| Material Monitoring: | Display indicates build and support material levels accurately in 10% increments |

| One-Click Software: | Automatically formats CAD files for 3D printing |

| CAD File Input: | .stl and .slc files |

| System: | Windows, PC-to-printer connectivity via high-speed USB 2.0 or Ethernet |

S325

| Layer Thickness: | 0.001 inch (0.0254mm) |

| Resolution: | 5000 dots/inch (197 X 197 dots/mm) in X, Y |

| Accuracy: | ±0.005 inch (127 μm) for 1st inch (25.4 mm), ±0.001 inch/inch (25.4 μm) each additional inch X,Y and Z |

| Surface Finish: | Layer thickness-dependent, up to 32 micro-inches (RMS) |

| Start Process: | Fully automated, one-touch operation |

| Status Monitoring: | Fully automated fault detection, restarts build from point of interruption |

| Calibration Capacity: | Quicker calibration and ability to select calibration frequency means less wasted material |

| Dimensions: | 21.4 x 18 x 16 inches (558 x 495 x 419 mm) |

| Build Envelope: | 6 x 6 x 4 inches (152.4 x 152.4 x 101.6 mm) |

| Weight: | 80 lbs (36 kg) |

| Power: | 100 - 240 V Required |

| Operating Temperature: | 60° to 75°F (16° to 24°C) |

| Humidity: | 40-60% |

| Agency Compliance: | CE Certified, FCC Class B approved, TUV certified EN 60950 Compliant |

| Midas Castable Material: | Proprietary model material formulated for clean burnout, producing 100% direct casting results |

| MeltDissolvable Support: | Proprietary support material engineered to dissolve completely, hands-free, resulting in superior surface finish |

| Material Capacity: | Larger tanks require less filling and allow for longer print runs |

| Material Monitoring: | Display indicates build and support material levels accurately in 10% increments |

| One-Click Software: | Automatically formats CAD files for 3D printing |

| CAD File Input: | .stl and .slc files |

| System: | Windows, PC-to-printer connectivity via high-speed USB 2.0 or Ethernet |

s350

| Layer Thickness: | User Selectable – 0.00025 inch (0.00635 mm) to 0.003 inch (0.0762 mm) at 0.00025 (0.00635 mm) increments |

| Resolution: | 5000 dots/inch (197 X 197 dots/mm) in X, Y |

| Accuracy: | ±0.005 inch (127 μm) for 1st inch (25.4 mm), ±0.001 inch/inch (25.4 μm) each additional inch X,Y and Z |

| Surface Finish: | Layer thickness-dependent, up to 32 micro-inches (RMS) |

| Start Process: | Fully automated, one-touch operation |

| Status Monitoring: | Fully automated fault detection, restarts build from point of interruption |

| Calibration Capacity: | Quicker calibration and ability to select calibration frequency means less wasted material |

| Dimensions: | 21.4 x 18 x 16 inches (558 x 495 x 419 mm) |

| Build Envelope: | 6 x 6 x 4 inches (152.4 x 152.4 x 101.6 mm) |

| Weight: | 80 lbs (36 kg) |

| Power: | 100 - 240 V Required |

| Operating Temperature: | 60° to 75°F (16° to 24°C) |

| Humidity: | 40-60% |

| Agency Compliance: | CE Certified, FCC Class B approved, TUV certified EN 60950 Compliant |

| Midas Castable Material: | Proprietary model material formulated for clean burnout, producing 100% direct casting results |

| MeltDissolvable Support: | Proprietary support material engineered to dissolve completely, hands-free, resulting in superior surface finish |

| Material Capacity: | Larger tanks require less filling and allow for longer print runs |

| Material Monitoring: | Display indicates build and support material levels accurately in 10% increments |

| One-Click Software: | Automatically formats CAD files for 3D printing |

| CAD File Input: | .stl and .slc files |

| System: | Windows, PC-to-printer connectivity via high-speed USB 2.0 or Ethernet |

s370

| Layer Thickness: | User Selectable - 0.00025 inch (0.00635 mm) to 0.0015 inch (0.038 mm) at 0.00025 (0.00635 mm) increments |

| Resolution: | 5000 dots/inch (197 X 197 dots/mm) in X, Y |

| Accuracy: | ±0.005 inch (127 μm) for 1st inch (25.4 mm), ±0.001 inch/inch (25.4 μm) each additional inch X,Y and Z |

| Surface Finish: | Layer thickness-dependent, up to 32 micro-inches (RMS) |

| Start Process: | Fully automated, one-touch operation |

| Status Monitoring: | Fully automated fault detection, restarts build from point of interruption |

| Calibration Capacity: | Quicker calibration and ability to select calibration frequency means less wasted material |

| Dimensions: | 21.4 x 18 x 16 inches (558 x 495 x 419 mm) |

| Build Envelope: | 6 x 6 x 4 inches (152.4 x 152.4 x 101.6 mm) |

| Weight: | 80 lbs (36 kg) |

| Power: | 100 - 240 V Required |

| Operating Temperature: | 60° to 75°F (16° to 24°C) |

| Humidity: | 40-60% |

| Agency Compliance: | CE Certified, FCC Class B approved, TUV certified EN 60950 Compliant |

| Midas Castable Material: | Proprietary model material formulated for clean burnout, producing 100% direct casting results |

| MeltDissolvable Support: | Proprietary support material engineered to dissolve completely, hands-free, resulting in superior surface finish |

| Material Capacity: | Larger tanks require less filling and allow for longer print runs |

| Material Monitoring: | Display indicates build and support material levels accurately in 10% increments |

| One-Click Software: | Automatically formats CAD files for 3D printing |

| CAD File Input: | .stl and .slc files |

| System: | Windows, PC-to-printer connectivity via high-speed USB 2.0 or Ethernet |

s390

| Layer Thickness: | User Selectable - 0.00025 inch (0.00635 mm) to 0.0015 inch (0.038 mm) at 0.00025 (0.00635 mm) increments |

| Resolution: | 5000 dots/inch (197 X 197 dots/mm) in X, Y |

| Accuracy: | ±0.005 inch (127 μm) for 1st inch (25.4 mm), ±0.001 inch/inch (25.4 μm) each additional inch X,Y and Z |

| Surface Finish: | Layer thickness-dependent, up to 32 micro-inches (RMS) |

| Start Process: | Fully automated, one-touch operation |

| Status Monitoring: | Fully automated fault detection, restarts build from point of interruption |

| Calibration Capacity: | Quicker calibration and ability to select calibration frequency means less wasted material |

| Dimensions: | 21.4 x 18 x 16 inches (558 x 495 x 419 mm) |

| Build Envelope: | 6 x 6 x 4 inches (152.4 x 152.4 x 101.6 mm) |

| Weight: | 80 lbs (36 kg) |

| Power: | 100 - 240 V Required |

| Operating Temperature: | 60° to 75°F (16° to 24°C) |

| Humidity: | 40-60% |

| Agency Compliance: | CE Certified, FCC Class B approved, TUV certified EN 60950 Compliant |

| Midas Castable Material: | Proprietary model material formulated for clean burnout, producing 100% direct casting results |

| MeltDissolvable Support: | Proprietary support material engineered to dissolve completely, hands-free, resulting in superior surface finish |

| Material Capacity: | Larger tanks require less filling and allow for longer print runs |

| Material Monitoring: | Display indicates build and support material levels accurately in 10% increments |

| One-Click Software: | Automatically formats CAD files for 3D printing |

| CAD File Input: | .stl and .slc files |

| System: | Windows, PC-to-printer connectivity via high-speed USB 2.0 or Ethernet |