World-class technology

Birmingham City University’s Jewellery Industry Innovation Centre (JIIC), part of the Birmingham School of Jewellery, is internationally respected for its expertise in utilizing highly complex CAD/CAM and laser technologies to provide small-scale product development solutions for companies.

“We work in conjunction with local industries to give them access to various high-end technologies that they might not normally have access to,” explains the JIIC’s Frank Cooper. “[The Centre] allows them to evaluate the potential for adopting those technologies into their businesses.”

A hoard of possibilities

The largest hoard of Anglo-Saxon gold and silver metalwork ever found, anywhere in the world, was discovered in Staffordshire, England in 2009. The Staffordshire Hoard, as it is now named, consists of more than 3,500 items tentatively dated to the late 6th and early 7th centuries. Since the discovery, research and conservation experts, including those from the Birmingham Museums Trust, have been working to learn more about the Kingdom of Mercian era artifacts and share the excitement of the discovery with the community. The Staffordshire Hoard is jointly owned by Birmingham and Stoke City Councils.

The museum approached the JIIC to help put Staffordshire Hoard pieces in the hands of the people, literally, by creating 3D printed replicas that could then be studied, seen, passed around and enjoyed by enthusiasts of all ages. The 3D printer of choice for such a project was clear to the JIIC from the start. For the high precision and castability required, it had to be Solidscape.

If we need some casting prototype produced that we are 99.9 percent certain will work in the casting process, then we will go to the Solidscape machines.

Frank Cooper Jewellery Industry Innovation Centre

A delicate balance

The duplicate cross, along with other and future replicas, allow for up close and personal, hands-on interaction with historical materials. The 3D printing process also allows for unique hypothetical prototyping. As well as creating the models representing the Hoard artifacts as they are now, the JIIC is using 3D printing technology to extrapolate what the objects would have looked like when they were first created.

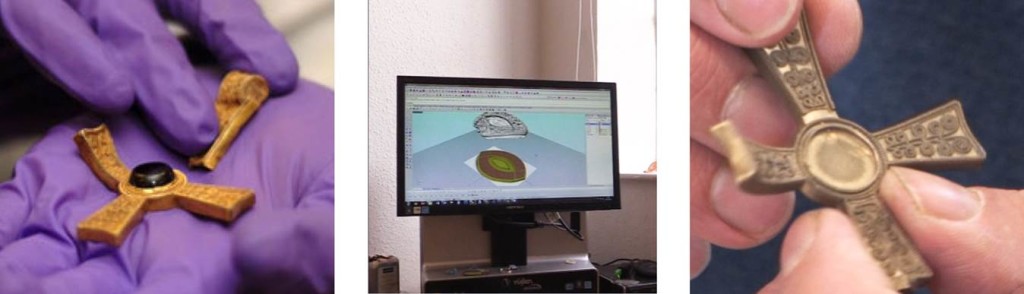

The Jewellery Industry Innovation Centre process from left to right: examine and study the original (left); create a 3D CAD model (center); 3D print on a Solidscape high precision 3D printer and cast the perfect replica.

The [Solidscape] build quality is fine, the repeatability is excellent and it’s pretty much ‘press go and leave.’ Our favorite process is to switch it on at night … and then take the stuff off the next morning and do all the final finishing. It’s never failed us.

Frank Cooper

“Being able to handle a replica artifact and examine the intricate designs up close enables visitors to experience the Staffordshire Hoard in a new way,” explains Pieta Greaves of the Birmingham Museums Trust. “It also critically widens access to the Hoard to include visitors with additional access needs.”