Alexandria Matossian of Bostonian Jewelers sat in the middle of the classroom, eager to start. “Before we get started on the history of CAD and 3D printing, let me tell you a little bit about myself.” Alexandria remembers being focused on everything creative ever since a young age and went to college planning to be an art teacher. A metal class helped her discover a passion for jewelry making. After school, she apprenticed for 7 years during which time she honed her skills as a bench jeweler through a lot of trial-and-error. When she discovered Computer-Aided Design (CAD) in 2000, she taught herself in a similar fashion. Since then, CAD software has been developed with features specific to jewelry design, making it more achievable for designers wanting to produce the objects of their dreams.

Today, Ali is the Creative Director of Bostonian Jewelers. Located in the historical downtown district, Bostonian’s is a small manufacturer as well as a high end jewelry retail store offering custom design services to their clients. Ali and her team work at a pace to meet a goal of designing a custom piece every day.

Ali’s love for what she does has inspired her to share the knowledge gained through 30 collective years of bench and CAD experience in her first Introduction to Digital Design & 3D Printing for Jewelry Making workshop at the New Hampshire Institute of Art in Manchester.

Paving the Way to Creativity

The class members range from bench jewelers to middle school teachers, some with and some without CAD experience. They all arrived anxious to learn and with many questions. Echoing Alexandria’s journey, they have been self-taught and were grateful to finally find a local workshop offering them the opportunity to take their skills to the next level.

“There are no CAD classes here in New Hampshire, so thank you so much for doing this.”

The New Hampshire Institute of Art was very excited to give Alexandria the opportunity to teach her workshop. James Chase from NHIA also attended the event, stating, “We are so thrilled about this collaboration and this series of hands-on weekend workshops designed to introduce everyone — from the traditional jeweler with no experience using digital technology to the designer comfortable using software design tools but no experience using 3D printing technology — to the potential of this new field of digital jewelrymaking.”

The Day began with an overview of the development of CAD and 3D Printing spanning four decades. When discussing the debate over the new way of thinking vs traditional jewelry making in the 1990s, Alexandria pointed out how Egyptians had used tools such as foot pedal torches to create jewelry. “Everyone uses their environment to create art and be creative. CAD is just another tool to get to that creative spot.” Alexandria compares learning new tools to children being like a sponge and soaking up new knowledge from the world around them. Her goal for the workshop is to provide what she never had, a teacher to help her students learn CAD.

“We can all be a sponge and find our creativity using this software together.” – Alexandria Matossian

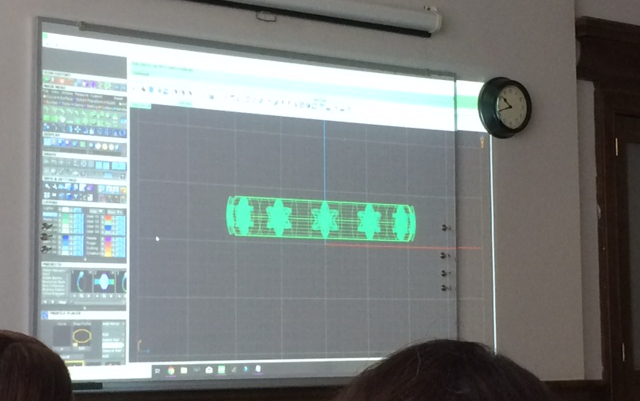

After the historical introduction, Alexandria dived into her CAD program, Matrix, for a quick demo.

“What should I make?” she asked the students.

“How about something floral?”

As she designed a single petal, multiplied it, and bent the petals to hug the band, she explained how CAD is similar to working on the bench. Even in a digital medium, CAD is all about sticking objects together and cutting things away to design a piece of jewelry. “The bench has no undo button,” she pointed out. “And work can be saved in CAD.” Ring profiles can also be saved in the CAD program to use over and over again. Alexandria scrolled through a “gazillion” saved profiles and chose her most often used profile, highlighted in purple.

“Today’s the day. I have a thought.”

A huge game changer that CAD and 3D Printing brought to Alexandria is the ability to build the design that was in her head at her pace rather than manufacturing’s pace. When she wakes up in the morning with a new idea, it’s no longer only in her sketchbook or on a “to do” list. She can sit down and design it in CAD. Sometimes she has no idea if the design will work as a finished piece. With her Solidscape 3D Printer, she can run a test print, and then return to CAD for any edits needed. At any time she can find old files that never made it to production years ago and bring them back into 2018 with new updates.

“Do you guys like Lord of the Rings?” she asked, referring to her beautifully detailed Elven Ring.

Hagop Matossian, her husband and CEO of Bostonian Jewelers, then began a story about the ring. “She made this ring so long ago.”

“Oh yeah, this was before I had a Solidscape!”

“She sent it to someone to print and they called back saying it was impossible.”

Today, Ali has the ring as a Solidscape 3D printed wax model and as a cast piece.

“Well, now we just have to see it!” the students said.

“Should I show it right now?”

As she opened the renderings of the ring and passed around the models and cast piece, she emphasized how important the ability to bring her ideas to life is.

“Being able to create what’s in your head, without any judgment might I add, is critical. It’s a good mental health thing as well.” – Alexandria Matossian

Learn Something New Every Day

After lunch, the class left their seats and headed outside the classroom into a wide open area. There, the Solidscape S390 High Precision 3D Printer rested on a table and 3D printed wax models were out on display. As the students filed in, excitement to see the printer and models up close started building.

Solidscape Senior Customer Support Specialist Matt gave a rundown on Solidscape technology and material. “The material is really where Solidscape excels in jewelry,” he explained, passing around a build plate with half-finished models on it. The red support material outlined the blue build material, illustrating how the two work together to create a smooth model. “Because our material is the best castable material.” Solidscape material performs the same as carving wax in the casting furnace, with no shrinkage and leaving no residue. The final casting retains all of the sharp detail the designer created in their CAD design.

Quickly, the demonstration became more interactive with the entire class getting a closer look inside the printer and admiring the display of printed models. There were many questions, swapping of stories, and sharing of advice. The teachers expressed interest in field trips to Solidscape in Merrimack if possible, which Matt happily affirmed. At the models table, Matt pointed out the amazing level of CAD design compared to what he used to see when he first started at Solidscape 13 years ago. Many of the sample models were winners and finalists from Solidscape’s Annual Design Competitions. It has been fascinating to watch as jewelry design progresses over time.

Hagop Matossian was enthralled with the designs as well, stating, “I’m always learning.” By the end of the demonstration, Alexandria echoed the sentiment, too. “I’ve been using this machine for years and I learned something new today!”

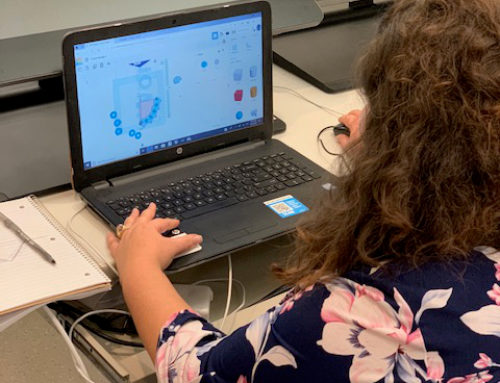

The fantastic day ended with time for the students to learn and experiment in TinkerCAD software with Alexandria’s one-on-one help. As the workshop continues, Solidscape is excited to see these designers learn and grow together through the opportunity NHIA and Alexandria have given them.

“We are a tight-knit community of creative thinkers, artists, designers, writers, and art educators who use the power of our creativity to transform the community around us.” – James Chase

Alexandria Matossian’s Introduction to Digital Design & 3D Printing for Jewelry Making workshop continues through October and November. Special thanks to Alexandria Matossian, Hagop Matossian, and James Chase from NHIA for inviting Solidscape to collaborate with them!